Every week, Rinchem shares important articles and topics about chemical and gas logistics, industries we operate in, and the general global supply chain. In this week's update we discuss the Dutch takeover of Chinese factory, a U.S./ Australia agreement, and the effects of climate change on supply chains.

Keep reading to see this week's hot topics.

This week's stats

At least $1 Billion- in financing for critical mineral projects in the U.S. and Australia within the next six months Supply Chain Drive

Battle between Netherlands and China over chipmaker could disrupt car factories, companies say

The Dutch government has stepped in to take control of Chinese-owned chipmaker Nexperia, citing national security concerns. This takeover has triggered retaliation from China—blocking exports from Nexperia—and raised serious alarms within the global automotive industry. Major manufacturers, including Volkswagen and Volvo Cars, warned their production might be disrupted because the chips in question are integral to vehicle control systems.

US, Australia sign framework for critical mineral supply chain

The United States and the Australia have signed a non-binding framework to collaborate on building a secure supply chain for critical minerals — minerals that are essential for both industrial and military applications — in response to tightening export controls by China. The agreement includes joint public and private investments in mining and processing, efforts to streamline permitting, and mechanisms like price floors to protect domestic industries. It also calls for the creation of a joint security-response group to address risks across the supply chain and bolster recycling technologies for critical minerals.

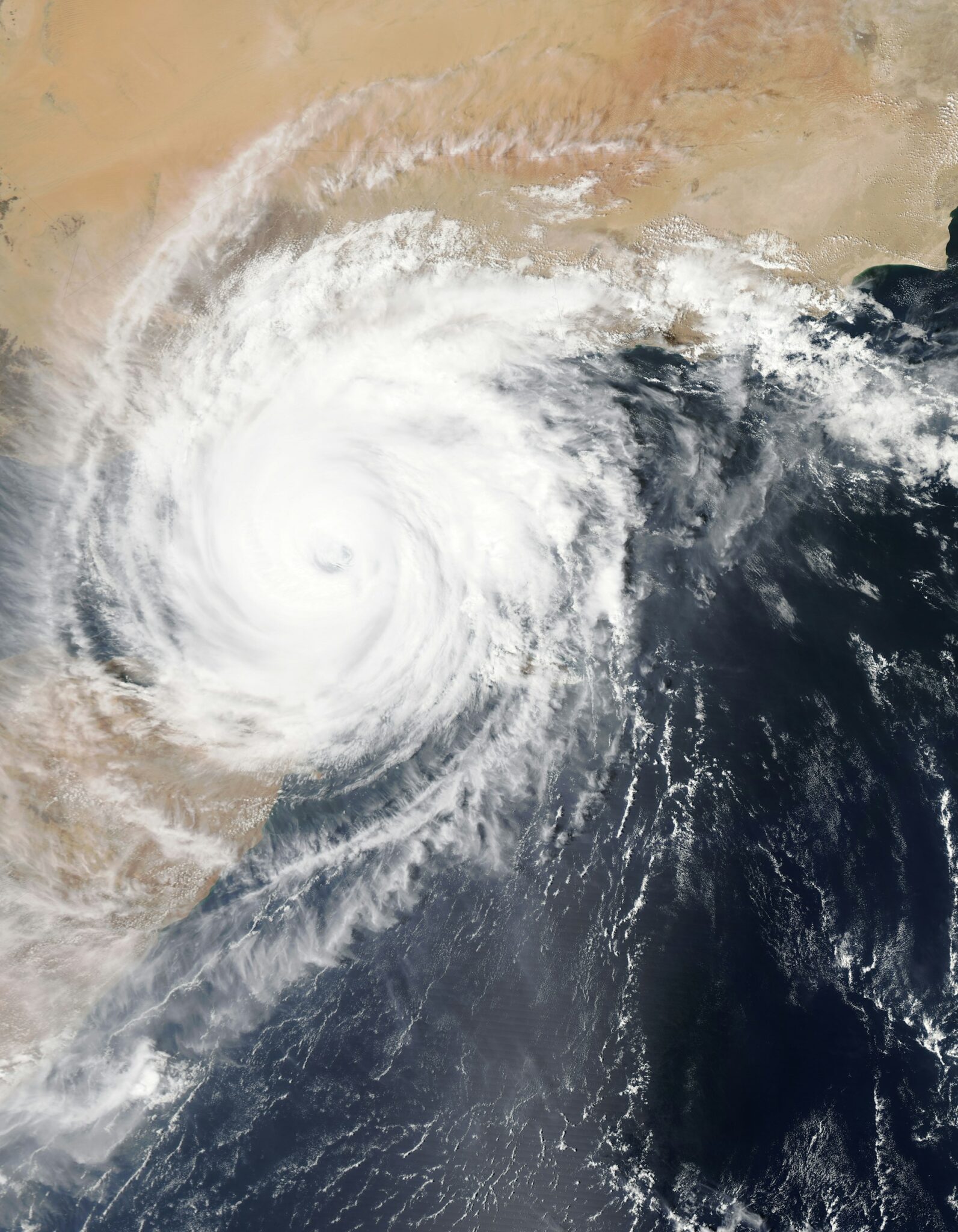

Climate Risk Is No Longer Optional in Supply Chain Management

The article argues that climate risk is now a core component of supply-chain management, not a side concern, because companies face increasing asset and operational disruptions from climate-driven events (floods, fires, heat) and must integrate climate analytics into resilience frameworks. It highlights that many supply-chain professionals are still treating climate and operational risks separately, even though resilient supply chains require merging climate risk and logistics, planning across functions (warehousing, transportation, sourcing) and improving supplier transparency. The piece emphasizes that current supply-chain resilience efforts (flexibility, contingency, collaboration) must evolve to explicitly include physical and transition risks from climate change.

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles