Every week, Rinchem shares important articles and topics about chemical and gas logistics, industries we operate in, and the general global supply chain. In this week's update we talk the future of the semiconductor industry, how supply chain management education is changing, and declining imports.

Keep reading to see this week's hot topics.

This week's stats

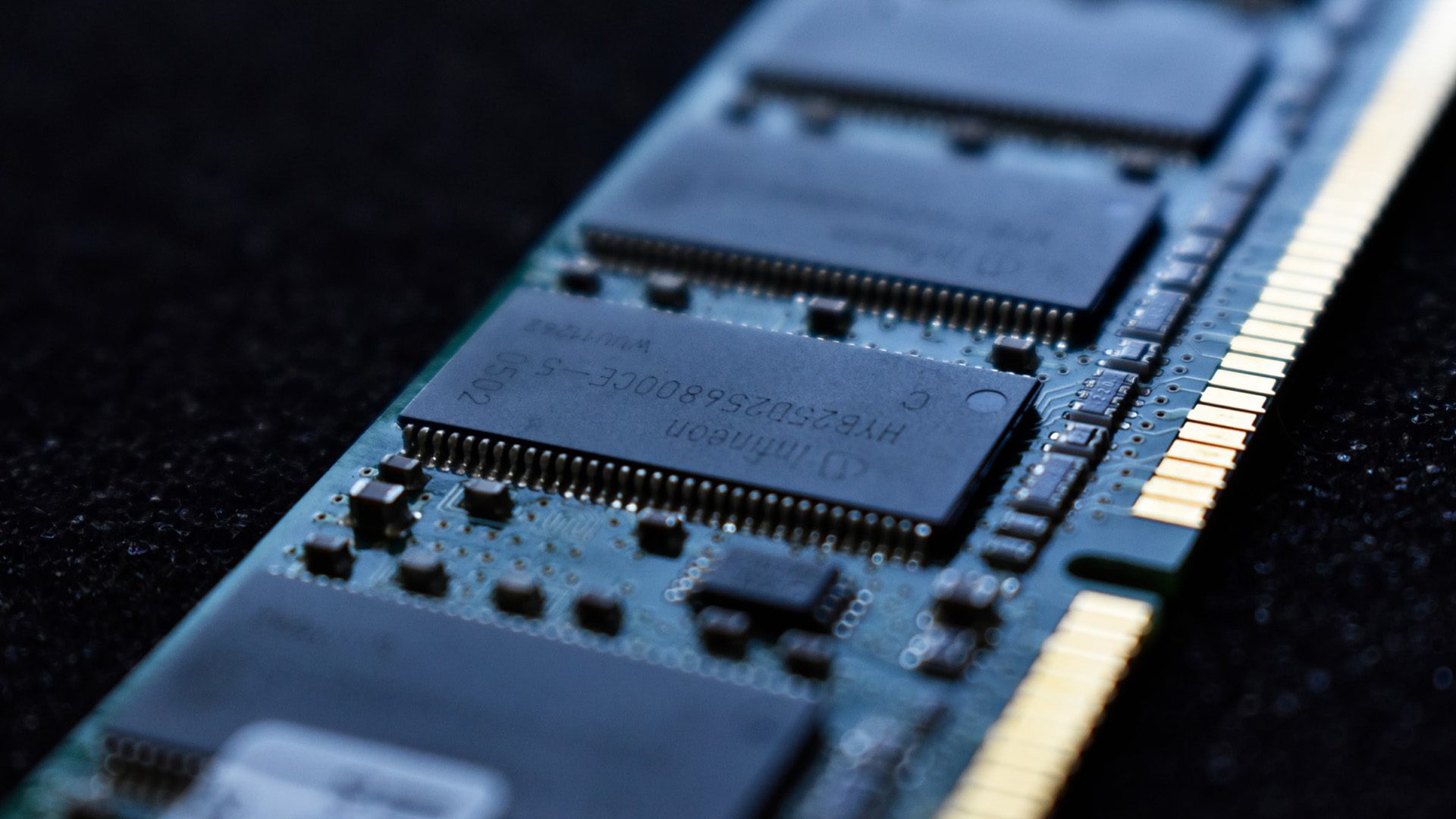

1,000 Steps- and about three months to manufacture a single semiconductor chip Semiconductor Engineering

2.36 Million- July's TEUs, the second busiest month on record Material Handling & Logistics

Lessons From 30 Years In The Trenches On The Future Of Semiconductor Manufacturing

In this reflective piece, John Kibarian, drawing on over 30 years in semiconductor manufacturing, argues that the industry’s future will hinge on AI-driven agility, deep collaboration, and resilient strategies amid geopolitical shifts. He underscores how deeply complex chip fabrication has become—lasting roughly three months and spanning more than 1,000 steps—requiring massive R&D and fab investments (like $5 billion on research and $15–$20 billion per factory) where even being second to market can spell financial ruin. Success now demands real-time, AI-enabled integration of engineering, operational data, and business decisions, exemplified by PDF Solutions’ tools like Sapience and secureWise, which connect hundreds of fabs and empower smarter, autonomous workflows. Kibarian also highlights emerging trends such as 3D advanced packaging, decentralized manufacturing (via initiatives like the U.S., European, Japanese, and Indian Chips Acts), AI augmentation to offset talent shortages, and a shift from volume-dominance to "learning from less," all while stressing the critical need to cultivate the next generation of semiconductor talent.

Supply chain management education boosts focus on resilience

Universities are rapidly revamping their supply chain management curricula to prepare future professionals for a volatile world marked by frequent and severe disruptions—ranging from natural disasters to pandemics and geopolitical strife. In response, institutions like Arizona State University (ASU) have launched initiatives (e.g., the Supply Chain Resilience Initiative) that embed risk-savvy, resilience-building concepts into core coursework, supported by research, workshops, and industry engagement. Marquette University offers a combined sustainability-and-resilience course focusing on visibility and multi-tier mapping, while Iowa State leverages deep ties with over two dozen companies to keep programs relevant to real-world supply challenges. The University of Tennessee, Knoxville, has overhauled its curriculum with a greater global focus and now offers an eight-week accelerated course for executives that addresses the inadequacy of traditional 30-day planning cycles in today's dynamic environment.

Imports Declining Following Summer Surge Ahead of Tariffs

The U.S. is now experiencing a downturn in import cargo volumes at its major container ports after a near-record summer surge driven by retailers rushing to stock up ahead of escalating tariffs—a strategy fueled by uncertainty in trade policy, according to the Global Port Tracker report from the National Retail Federation (NRF) and Hackett Associates. In July, ports across the country handled 2.36 million TEUs, marking a 20.1% increase from June and a 1.8% year-over-year rise—making it the second-busiest month on record, after May 2022. However, forecasts project a steady decline for the remainder of the year: September is expected to see 2.12 million TEUs (down 6.8% year-over-year), October at 1.95 million TEUs (down 13.2%), and November at 1.74 million TEUs (down 19.7%).

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles