TABLE OF CONTENTS

About the Case Study

Imagine the impact of saving millions on your global supply chain.

This case study explores how Rinchem’s 4PL services created significant cost savings for a

Fortune 500 company through comprehensive management of their global supply chain.

The Customer

What is a 4PL?

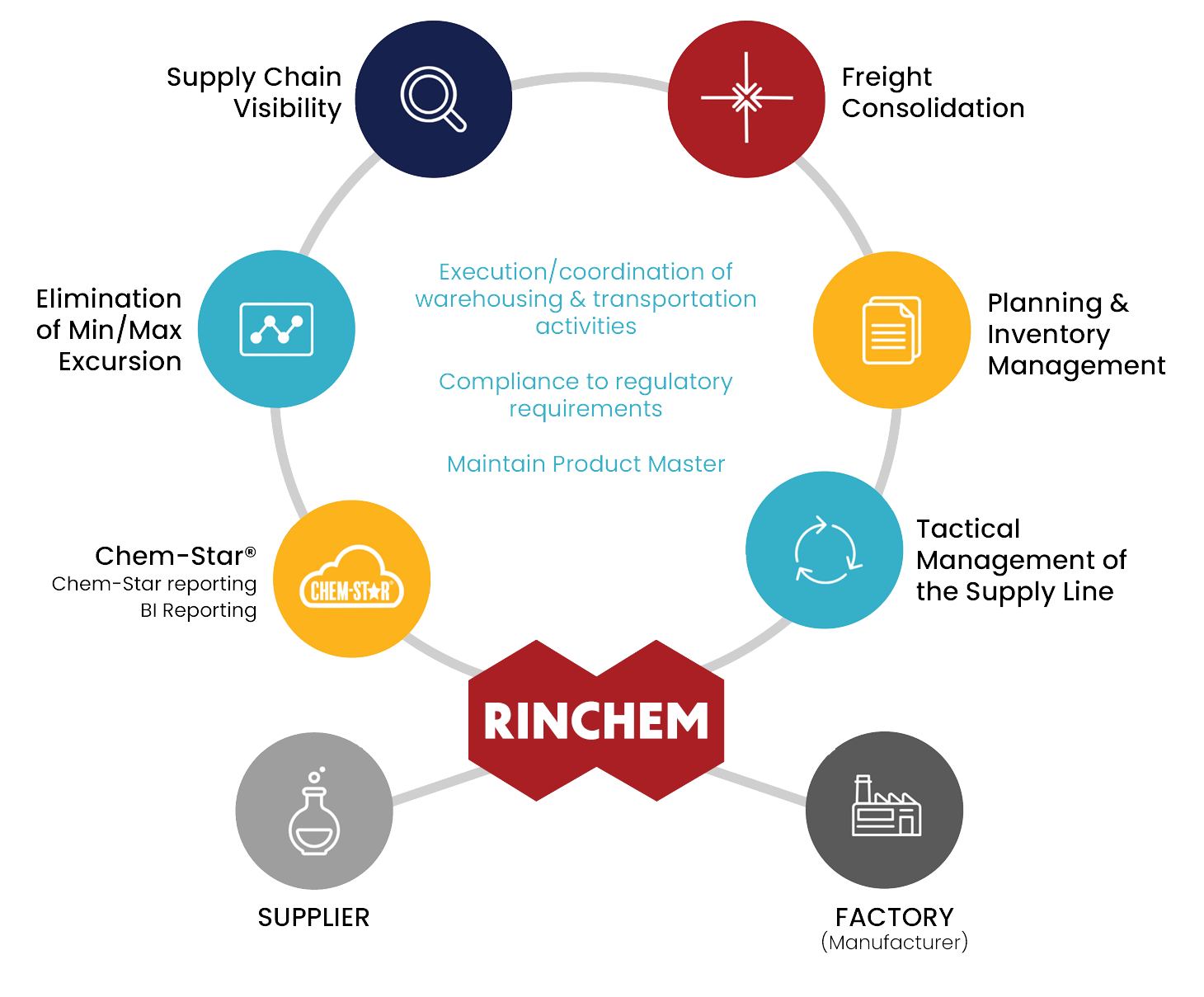

A 4PL (fourth-party logistics provider) provides a holistic turnkey approach to global supply

chain management that strategically integrates demand forecasts, manufacturing schedules,

warehouse management, domestic and international transportation, inventory optimization,

and fulfillment of a customer’s material requirements. By coordinating suppliers and leveraging

technology, a 4PL service-provider enhances efficiency and minimizes supply chain risk, thereby

allowing businesses to focus on their core business.

Warehousing

Ground Transportation

Air & Sea Transportation

Materials Requirement Planning

Technology

How do 4PLs differ from 3PLs?

A 3PL (third-party logistics provider) executes the supply chain plan provided by the customer.

In doing so, a 3PL handles the day-to-day tasks provided by the customer such as warehousing,

picking and packing orders, international freight forwarding and transportation services.

In contrast, a 4PL manages the responsibilities for all 3PL services in addition to providing supply

chain services to enhance overall customer performance. For example, a 4PL creates the plan

for execution based on knowledge of the customer’s operations, customer demand, lead times,

transit times and production schedule. This 4PL coordination of supply chain with 3PL services

allows for an integrated end-to-end solution for the customer that minimizes risk and ensures

the lowest total landed cost.

4PL SERVICE FEATURES

Elimination of multiple hand-offs & third-party providers

Material requirements planning

to meet replenishment demandsGlobal door-to-door management

Cost visibility

Cost avoidance

Track & Trace

Case Study

The Problem

Scope

Rinchem conducted a cost analysis for nine materials for which the complete supply chain

fulfillment was managed in a 4PL model. Performance was measured over the course of a year.

1 Year

9 Products

Case Study Results

The results of the case study highlight significant benefits. By utilizing Rinchem’s material

management team, the customer achieves a 60% improvement in maintaining inventory

levels within stipulated parameters, all while avoiding additional risks to the supply chain.

The aforementioned inventory improvement over a year, across 9 materials accounts for:

Freeing up

in tied up in Working Capital

Reduces risk of additional losses to either requalify or dispose of material

Increases customer cash reserves

Saving

$5.6 Million

in Operating Expenses

Reduce storage fees for usable materials

Eliminate storage fees for obsolete materials

Minimize stockout occurrences and expedited freight costs

4PL Service Benefits

Optimizing for Success with Rinchem

Real-Time Visibility

Collaborative Inventory Management

We act as an extension of your team, fostering collaboration with your

suppliers. We manage production schedules, replenishment cycles, and

supplier inventory levels to ensure alignment with actual consumption

patterns. This reduces the risk of overstocking or understocking and optimizes

raw material usage.

Data-Driven Inventory Optimization

Rinchem leverages data analytics to identify optimal inventory levels for your

business. We utilize historical and forecasted consumption data to determine

the right balance between minimizing risk and maximizing efficiency.

More Benefits

Significant cost savings

Minimize supply chain risk

Streamline working capital

Enhanced disruption

preventionIncrease logistics buying

powerMitigate storage capacity

constraintsCreate a lean and resilient

supply chainIncrease efficiencies for

both the customer and their

suppliersMinimize obsolescence and

disposition costs

Next Steps

Curious What a 4PL can do for Your Supply Chain?

Thank you for exploring this case study. If you’ve made it this far, it’s clear that optimizing your

company’s supply chain is a priority—and you may be facing logistics challenges that require

real, actionable solutions.

At Rinchem, we specialize in navigating the complexities of third- and fourth-party chemical

logistics, operating in one of the most demanding industries. With nearly five decades of

experience and a proven track record, we’re proud to be leaders in this highly specialized field.

We thrive on tackling challenges—let’s work together to uncover cost-saving opportunities,

increase your supply chain resilience enhance efficiencies, and address the unique obstacles

your business faces. Whatever is keeping you up at night, we’re here to help.

Challenge us. We're Ready.

Discover what Rinchem’s Materials Management Team can do for your supply chain.

Schedule an introductory meeting today:

CustomerSolutions@rinchem.com

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles