In this case study, we explore a specific cost benefit and efficiency that companies can achieve when they integrate their supply chain management systems with Rinchem’s Chem-Star®

The Company

Rinchem works with many Fortune 500 companies across the globe. Our level of partnership with many of our customers often means sharing a customer’s name may divulge proprietary information. This is a real customer and a real case study.

Rinchem has had the pleasure of being a partner with this specific chemical manufacturer for over 15 years. They are a major supplier of materials, chemicals, and gases to the life science, semiconductor, and electronics industries. This company is a prominent user of our supply chain and warehouse management technology Chem-Star®.

The Problem

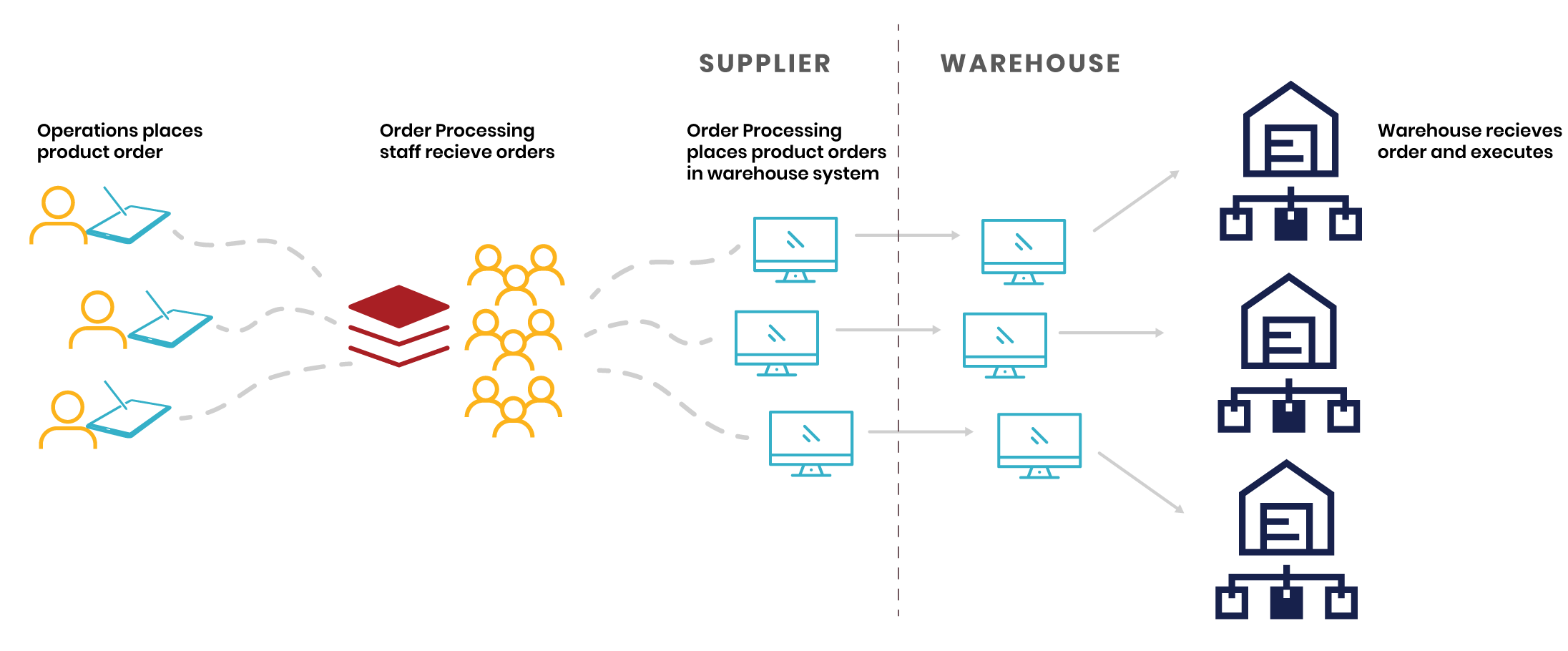

Our client, like many other global suppliers, are constantly ordering the movement of product, both inbound and outbound from Rinchem’s warehouses. The problem in this specific case is once an internal order is placed, someone needs to place the order externally with the third-party logistics provider (3PL).

What is Chem-Star®

Chem-Star® is Rinchem proprietary supply chain software that allows companies to:

- Gain real-time visibility of current supply in Rinchem warehouses

- Maintain material specifications to include temperature required for storage/shipping, regulatory data, end user part numbers, etc

- View a plethora of advanced analytics to support decision making, planning, and forecasting

- Order the sending and receiving of product

Chem-Star® Integration

In comes Chem-Star® Integration. Rinchem enhanced our technology offerings to help solve this costly and redundant process. While this client has been a super-user of Rinchem’s Chem-Star® platform, they just recently went through a full integration with Rinchem.

What is an Integration?

An integration, as it relates to Chem-Star®, is the connecting of Rinchem’s Warehouse Management and billing system with a company’s own internal system.

What does it mean?

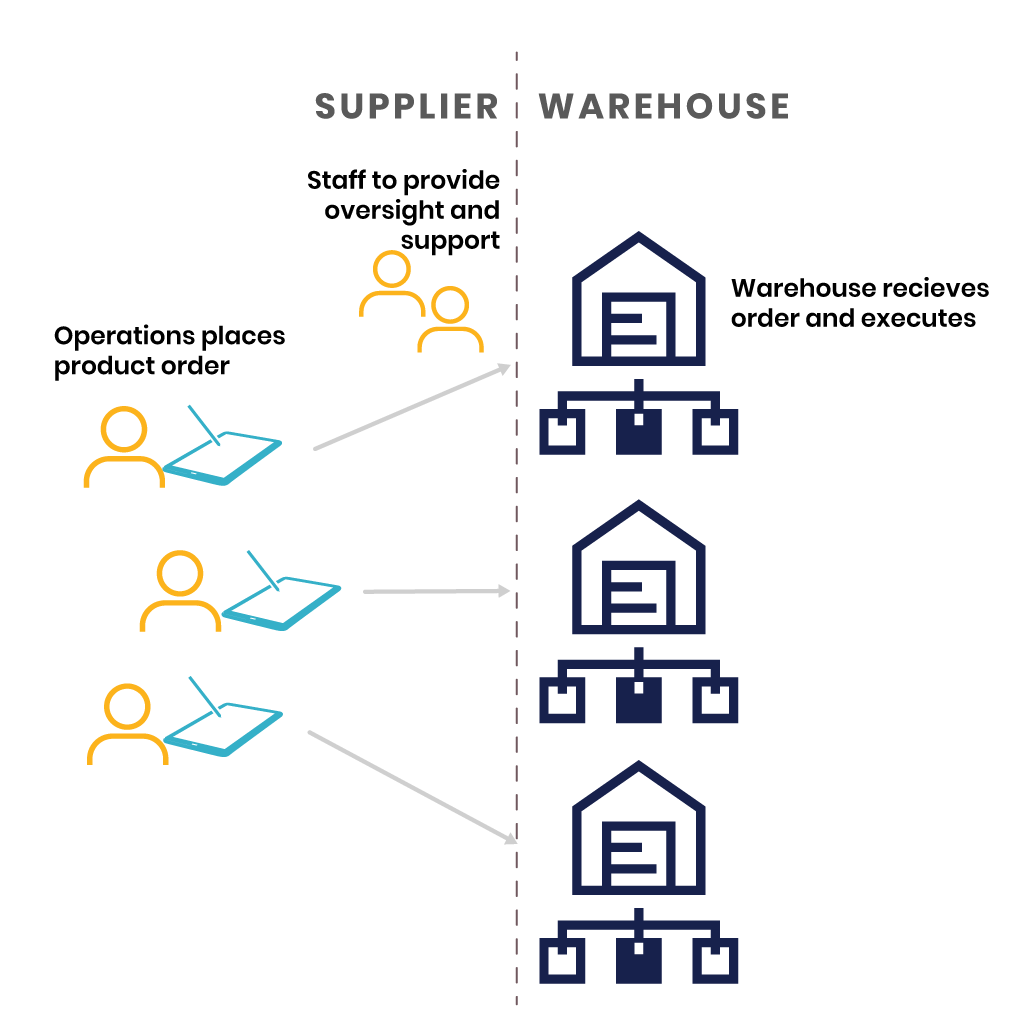

An integration removes many duplicate processes regarding the management of chemicals and gasses. When an order to deliver or receive products to and from a warehouse is made in the client’s system, that order is automatically communicated to the Rinchem warehouse. This eliminates the need for a person to place their internal order and then also manually place it with Rinchem.

The Results

After integrating their system with Chem-Star®, our client was able to shrink their workforce dedicated to these processes from 360 weekly human hours down to 80! Additionally, the client’s order error rate dropped to nearly a nonexistent level. The client has expressed their appreciation and now enjoys a faster, more efficient, less error-prone process as manual order entry has been removed.

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles