Ocean Shipping Container Consolidation

Case Study

A Fortune 500 semiconductor manufacturer with a vast supply chain was looking to cut their International Freight Forwarding costs.

The Problem

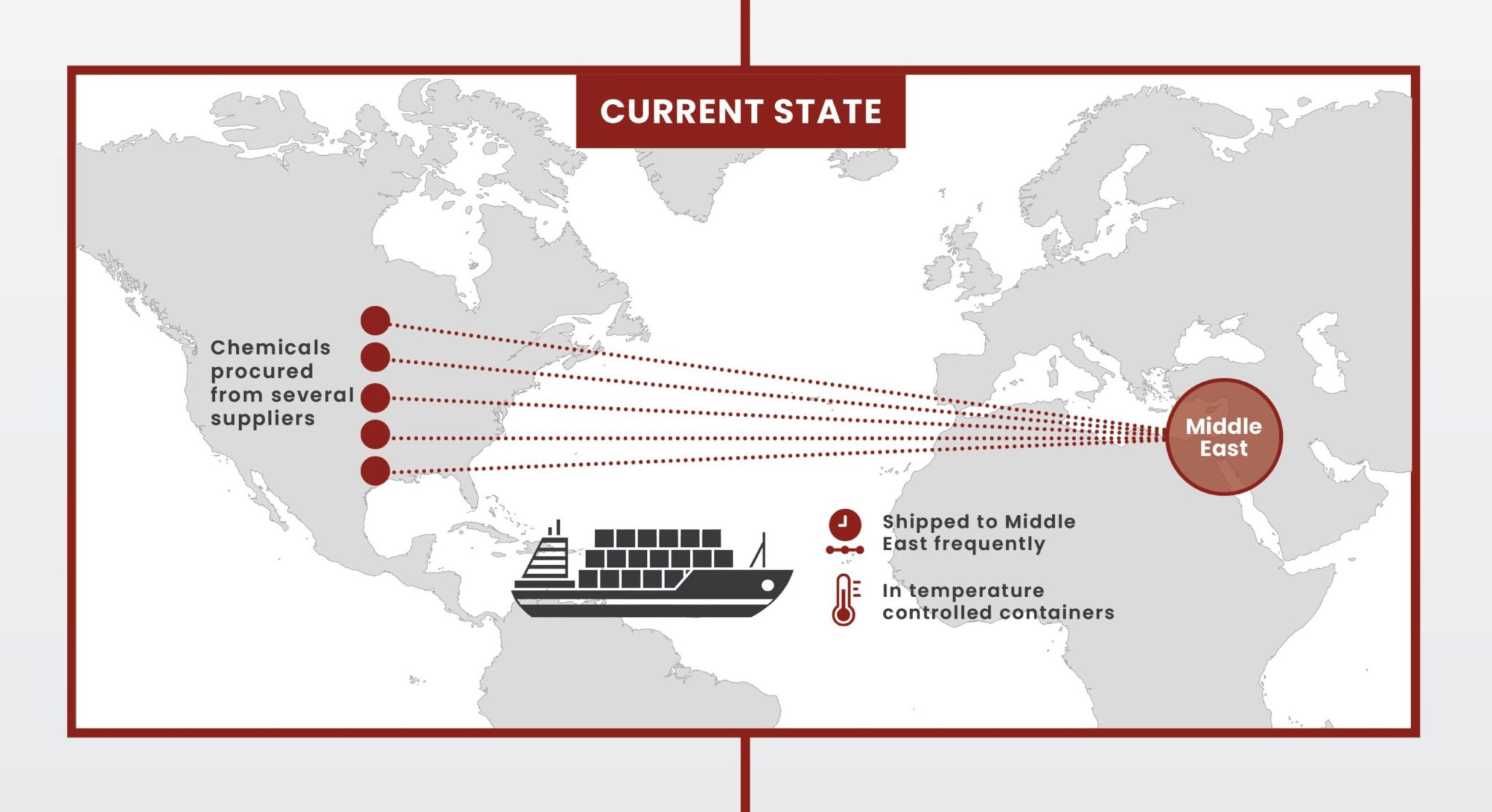

The manufacture needed to provide materials for use overseas in the Middle East. The current model saw shipping containers being sent across seas without fulfilling cubic volume due to weight restrictions. As a result, the ocean shipments were high per container due to the temperature control requirements for the material being shipped.

The Solution

To fully understand the needs Rinchem conducted an audit of the current state of the supply chain and shipment flow for these materials being shipped internationally to the Middle East.

1

Determine Consolidation Point

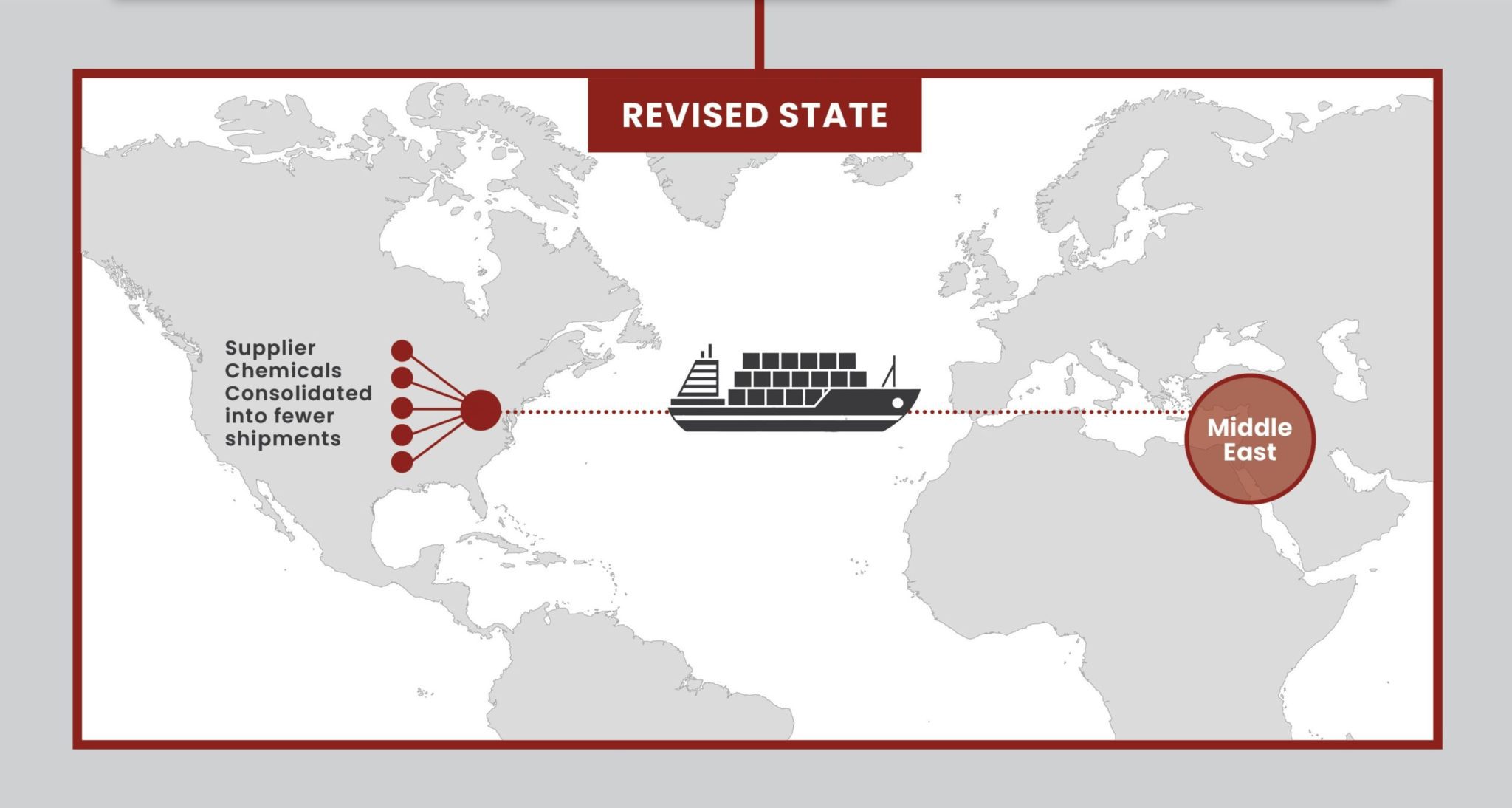

Rinchem obtained overweight permits to increase the ocean container payload weight allowing Rinchem to pack containers closer to the cubic volume capacity.

2

Increase Container Payload Weight

Rinchem determined consolidation points that each shipment would run through prior to being placed on an ocean container. Material was then consolidated into the fewest amount of shipments possible.

3

Cleared Up Current Staff Schedules

Allowing a single company to handle these international freight shipments. This cleared up hours off their current staff’s schedule to focus on other issues and projects.

↑15-25%

Increase in Payload Weight

86%

of Containers Configured to Leverage Overweight Permits

14%

Total Savings in Ocean Shipping Costs

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles