What are Consolidation Points and Cross-Docking?

Considering all the recent global supply chain challenges, incorporating consolidation points and cross docking into your logistics strategy could help streamline your operations. A consolidation point is a process of combining multiple shipments into larger loads and cross-docking works to receive and ship items out the same day without putting anything into storage. These two strategies combined provide several benefits like reducing shipping times while decreasing costs and risks. However, to reap the full benefits of these tactics, they must be executed properly. For Rinchem, proper implementation is even more crucial in our specialty of managing hazardous material and dangerous goods.

Definitions

Consolidation Points (CP)

Process of combining multiple shipments into larger loads.

Cross-Docking

Receive and ship items out the same day without putting anything into storage.

The Benefits of Consolidation Points and Cross-Docking

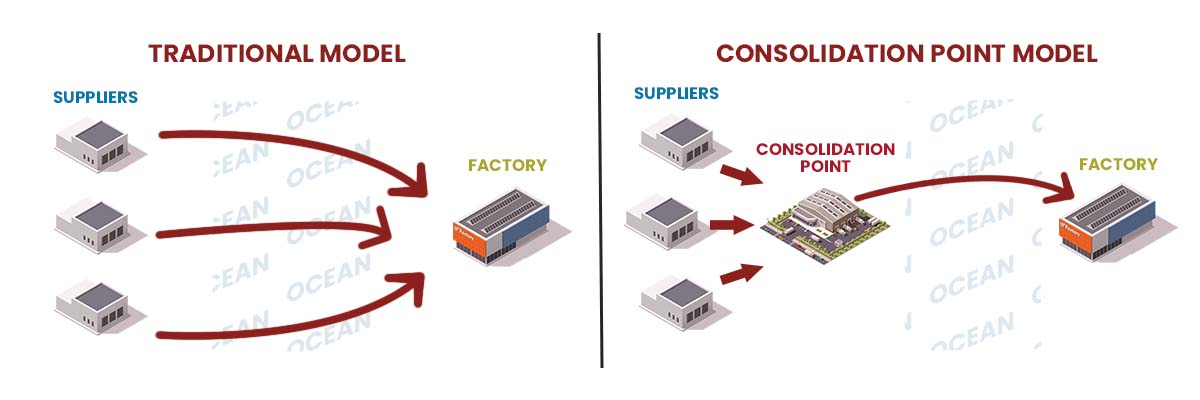

The traditional warehousing model typically uses a point-to-point model where freight is shipped and stored at a warehouse and eventually distributed to the freights’ end destination for use. Cross-docking uses a hub and spoke model to connect the dots between the maximum number of delivery destinations with the fewest number of routes/shipments. Most companies will benefit from using these methods, but industries like the semiconductor or chemical world especially reap the advantages.

-

Save Time

Cross-docking allows 3PLs (third party logistic providers) to decrease the total amount of time it takes to ship freight by focusing on the JIT (just in time) shipping process. Products quickly move from one step in the supply chain to the next. For example, shipments are immediately transferred from an inbound to outbound delivery. In return, products are processed faster, holding times are greatly reduced and each product reaches its end-user faster.

-

More Cost Effective

With less inventory handling comes a reduction in labor and storage costs, plus it decreases the risk of damage. When you consolidate smaller shipping systems into a single operation, it allows for multiple companies to share the cost of a shipping container.

-

Minimize Risk

Rapid throughput in your supply chain reduces the number of touch points. Every human touch increases the possible risk that an error will happen.

-

Other Benefits

Container consolidation, container utilization, ability to hold inventory to avoid over max situations, supply line flexibility, ability to provide pull model from CP locations, overflow capabilities and scenario planning to include CP inventory.

Proper Execution is Key

Consolidation and cross-docking require a level of expertise and infrastructure in order to execute it correctly. For many logistics managers, these strategies are often complicated and a detail-intensive task. Because of the unforgiving nature of this type of operation, Rinchem recommends you have a few things in place before putting anything into practice.

-

Customer Relationships

Rinchem works with a variety of chemical suppliers who provide high purity chemicals and gasses to several companies in the semi-conductor industry. So instead of having fifteen suppliers ship individually, we’ll often work with these suppliers through our Total Materials Management (TMM) Team. From there, we can work to get the products consolidated. Our relationships with both suppliers and manufacturers are a crucial aspect in being able to execute consolidation and cross-docking.

-

Logistics System

When you’re managing cross-continental products, today’s complicated supply chain requires a robust logistics system. Rinchem utilizes, Chem-Star®, our proprietary warehousing and transportation management system, which allows us to understand how to best move and store products to take advantage of things like consolidating compatible hazardous material. When everything links to a central database, you can more easily and accurately plan product movement.

-

Transport Fleet

While Rinchem does offer brokerage in our transportation services, having an asset fleet is what really grants us the flexibility to execute what’s needed for a consolidation points and cross-docking strategy. When you are wholly in control of a truck’s dedicated schedule, you can time everything much better.

-

Location

The strategic placement of a company’s global locations is important because it helps streamline the shipping process. A company’s supply chain is simplified when things can more easily go from point A to point B.

-

Niche Experience

Every industry has varying standards and regulations. So even if you have the infrastructure to handle consolidation and cross-docking, you’ll also need the expertise to understand what items can be grouped together. For Rinchem, we specialize in handling dangerous goods. This is especially important in our industry because of the product’s hazardous nature. For example, some products can only be grouped into certain hazard classes and some products can only be stored so long before it begins to eat through the container. Rinchem also manages non-hazmat and finished goods where we apply the same expertise in our packing methodologies. All these variables require a deep understanding of chemical regulations while maintaining strict safety standards.

Consolidation and cross-docking are smart practices that all logistics and supply chain management companies should consider. It’s a great way to improve your supply chain operations by saving time, cutting costs, and reducing risk. To implement these strategies properly, 3PLs need to make sure they have a great logistics system in place, a transportation fleet, strategic global placement, and industry expertise. While it can be a complicated and resource intensive task, it can be well-worth the benefits it provides when properly executed.

Get more articles like this in your inbox

Sign up for our monthly newsletter

Find more articles